Loading docks safety - Pedestrian protection

How to protect the staff, buildings and dock equipment? How to control risks?

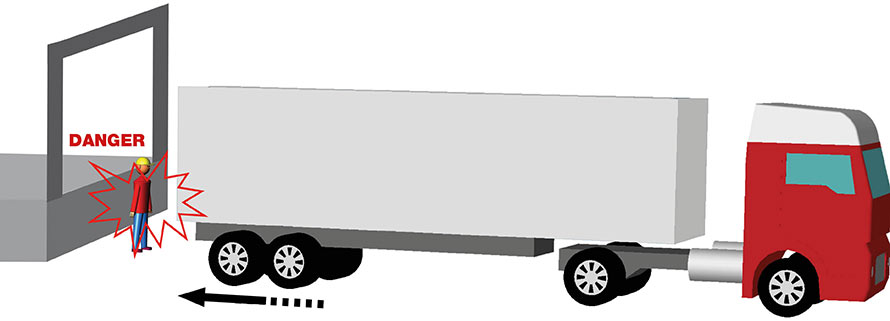

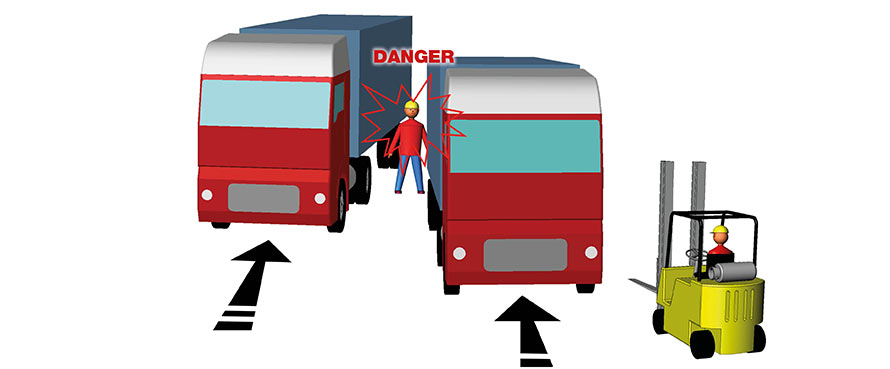

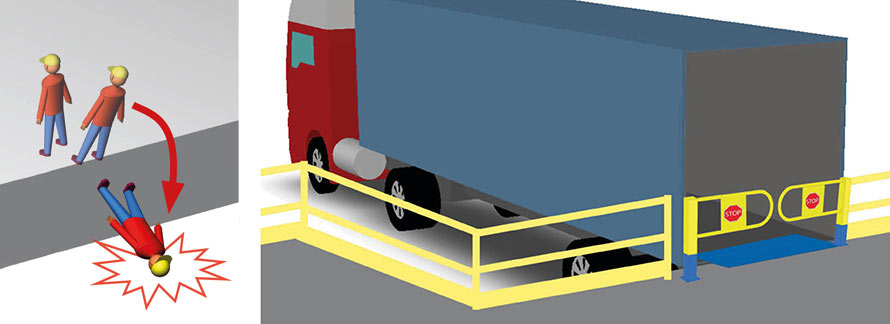

Loading and unloading operations generate a high risk of accidents. The main risks are vehicle-pedestrian collisions, crashing against docks, falling of people and handling equipment from the loading dock.

Here are our solutions to ensure the safety of docks, protection of people and protection of the dock installations:

Dock manoeuvring and transshipment operations generate risks of serious or even fatal accidents.

To comply with the NF EN349 standard and the INRS technical guide ED6059 of the INRS / CRAM taking into account the recommendations of the good practices of the profession and in order to guard against the risk of crushing people, we recommend you:

A) 800 mm telescopic lip dock levelers

The telescopic lip makes it possible to cross the anti-crushing safety zone. The solution is to build an adjustable loading ramp into the structure of the dock and install bumpers to reserve a 500 mm safety space. You will then be compliant with the NF EN 349 standard covering risks of crushing the human body.

B) Dock levelers with anti-fall lip and refuge zone

The BODY GUARD dock leveler Expresso has 2 safety devices:

- Anti-crushing system to protect people during the truck’s approach (refuge area)

- Anti-fall lip preventing forklifts from falling down the dock (See III Risk of dock falls in the event of unexpected departures).

At rest, the lip extends outwards (on top of the leveller) and forms an obstacle inside the building, protecting the door from impacts when it is closed and preventing handling equipment from falling down when it is open.

C) Draw-bridge levellers with safety zone

This type of very strong aluminium ramp can be installed on a dock with the addition of bumpers directly on the dock or installed on a one-piece frame incorporating a refuge area. The one-piece frame also ensures that trucks dock properly and protects dock equipment from impacts when docking, guaranteeing the longevity of the equipment.

Where there are no or inadequate* wheel guides, there is a real risk of pedestrians being crushed between two vehicles or between a vehicle and a building. There is also a greater risk of collision between two vehicles. That's why it's often necessary to canalise trucks to reduce the risk of accidents.

(*) NB: A wheel guide must be at least 2200 mm long and 260 mm high.

A) Metal wheel guides for dowelling or embedding

The wheel guides are a simple and cost-effective way of optimising the docking of lorries. They protect vehicles, people, buildings and dock equipment (bumpers, levellers, dock shelters), and help to improve loading dock safety.

(*)NB : A wheel guide must be at least 2200 mm long and 260 mm high.

B) Concrete wheel guides

The Concrete wheel guides are very resistant to shocks, their rounded shape makes it possible not to damage the vehicles in the event of a bad trajectory.

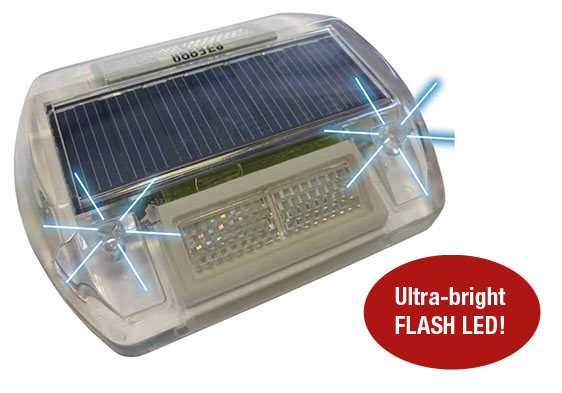

C) Signage using ground markings or lighting

The wheel guides can be supplemented by ground markings about 15 metres long at the front and by the installation of KIGR001 dusk sensor-operated lighting used to make night operations safer and easier.

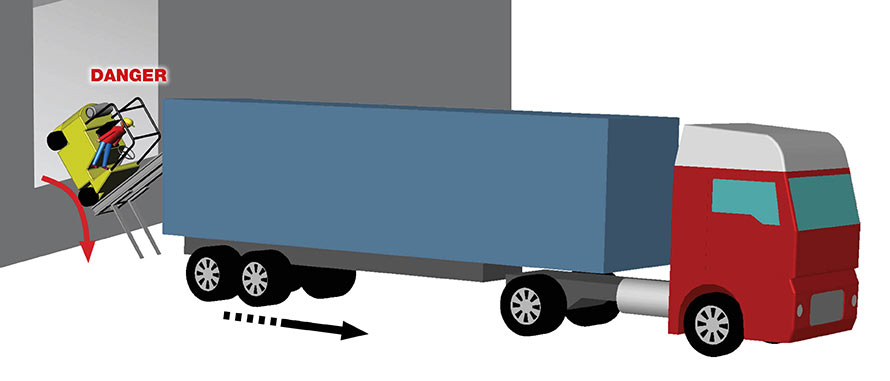

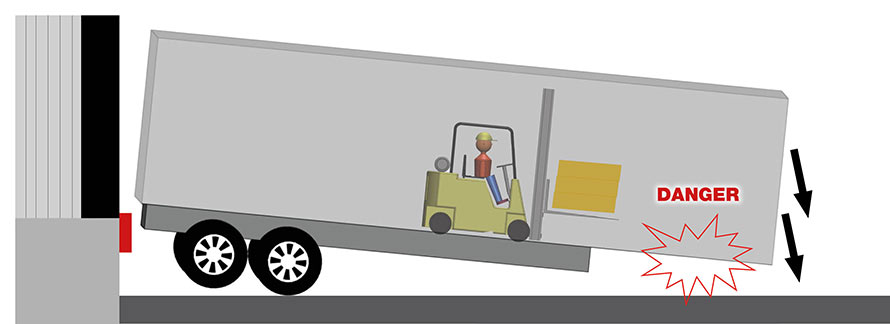

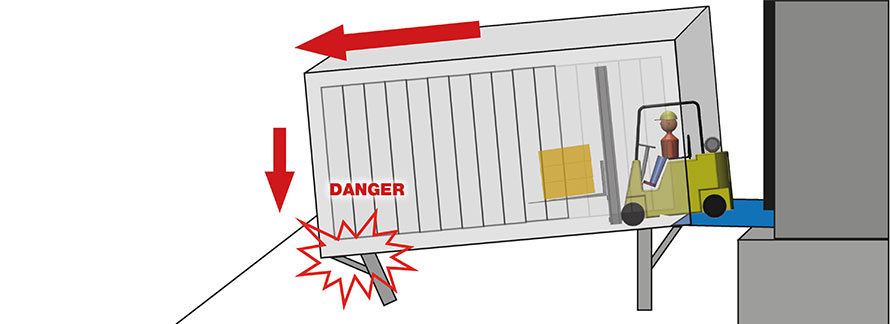

Transshipment docks are areas with a high accident risk. A forklift truck may fall before docking or during transhipment operations, in the event of untimely departure of the truck, due to human error, an incorrectly applied parking brake or an inverted slope of the berth.

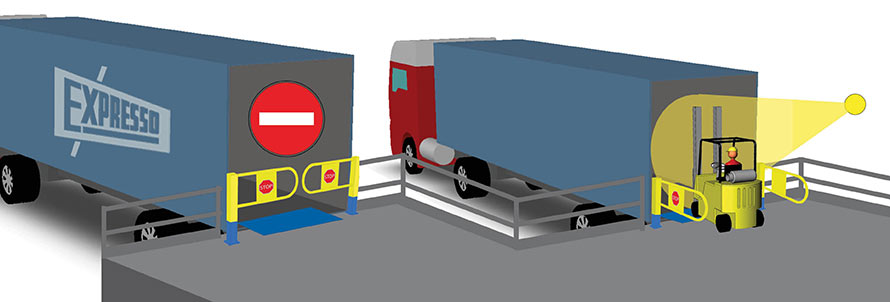

A) Wheel chock system or vehicle restraints

- Stop Trucks®, Patented automatic truck immobilisation system

The locking arm of the Stop Trucks® rises in front of the truck wheel without contact and then presses against the tyre with a slight recoil movement. The locking height varies automatically according to the diameter of the wheel to ensure optimum locking. The truck is then immobilised at the dock.

- BRMA Manual blocking system for trucks, Patented system

Manual locking is quick and easy. The driver uses the telescopic lever to slide the locking arm up to wheel level, then lowers it to deploy it. When the locking arm is raised in front of the truck wheel, the safety lock is activated by an "operator validation" switch or, as an option, automatically by the door or dock leveler.

The electric wheel chocks Expresso has a detection system which, when the chock is in contact with the wheel, sends the information to a traffic light control system and to the dock equipment. Opening the door and installing the leveller can therefore be made dependent on the chock being correctly positioned under the lorry wheel, thus ensuring that the trailer is properly secured during loading and unloading operations.

Risk of pedestrians or handling equipment falling from the loading dock.

A) Swivelling dock barrier

Automatically locking swivelling dock barriers are controlled by the dock equipment. They temporarily prevent access to people and vehicles. A barrier, for example, can be locked as soon as a platform lift descends, thereby preventing any risk of the platform falling.

B) Loading dock railing and other loading dock installations

Secure the transshipment areas with dock railings (supplied by the linear metre with dowel plates) and other features such as gravitational gates or dock stairs.

C) Barrier lip leveller with safety zone

Body Guard barrier lip dock Leveler has a double safety device : a anti-crushing device for people at the loading dock and a anti-falls system on the loading dock. At rest, the retracted lip creates an obstacle in the building (above the leveler) that protects the door from impact and prevents the fall of the forklifts when the door is open.

There is a risk of unhitched trailers tipping over during loading operations using a fork lift if the trailer parking legs fail or break.

A) Safety stands for trailers

The trailer jack stands are used to support the trailers during transshipment when the trailers are not hitched to the trucks. Their height can be adjusted using a crank or a jack.

The safety trestle does not directly support the unhitched trailer, but is placed underneath it to secure it if one of its parking legs fails or breaks. It does not have a raising jack, but its height is adjustable (using pins). The reinforced model is perfectly suitable for pneumatic suspension trailers.

C) Safety trestles to secure the rear of trailers

- Lowered and extended JACK/TM trestle Ref. TRMO1800

This safety trestle is designed to prevent the collapse of air-suspension trailers, and is positioned at the rear of the trailer.

- Reinforced mobile trestle 25 tons - Ref. TRMO40

Perfectly balanced, this trestle remains horizontal when set up. The height of the frame can be adjusted quickly and accurately by crank. It can be fitted to the rear of trailers.

During loading and unloading operations of swap bodies with a forklift truck, there is always a risk of it tipping over, collapsing or moving unintentionally.

A) Stand for swap bodies

The Stop Bodies is used to support and lock the swap body, preventing it from moving forwards or backwards from the dock. The locked box can neither move nor be removed by a truck while loading operations are in progress. Transhipment is totally secure.

Limiting the risks of collisions due to lack of lighting.

When the light inside trailers is reduced, or when working at night, it is important to have a directional light source in addition to any lighting installed on the handling machinery because its effectiveness is often limited by the transported load.

A) Dock lights

The installation of additional lighting provided by dock lights allows the most dangerous areas to be illuminated and eliminates light contrasts that require the pupil to adapt, a potential source of danger. CE products conform to the following directives: Directive 2004/108/EC - Directive 2006/95/EC - Directive 2011/65/EC.

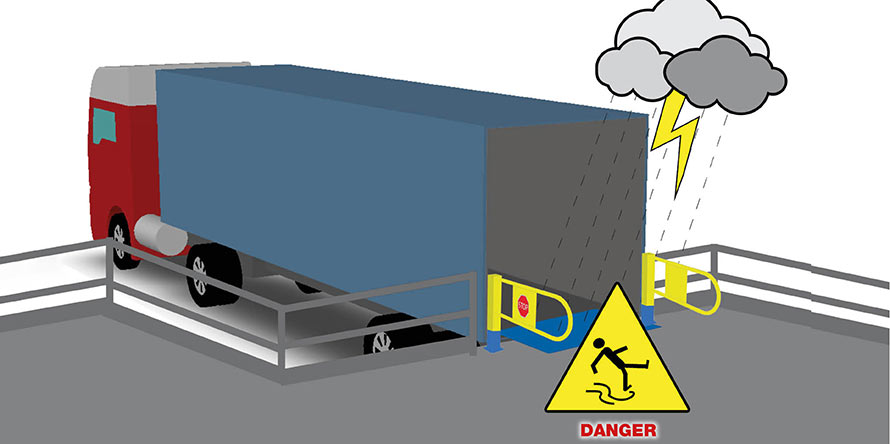

If there is no porch roof, or if it does not provide effective protection for the dock, the risk of slipping during transhipment operations is increased by rain and frost.

Protect transhipment areas from bad weather.

A) Loading tunnel with dock shelter

The tunnels for levelers ensure comfortable working conditions, protecting both people and goods, particularly when the building has no porch roof in the loading area or one that is too short.

B) Inflatable dock shelter

The inflatable dock shelter provides a sealed connection between the back of the truck and the warehouse wall. It is used to minimise heat loss and protects staff from bad weather during operations to load and unload trailers on the docks.

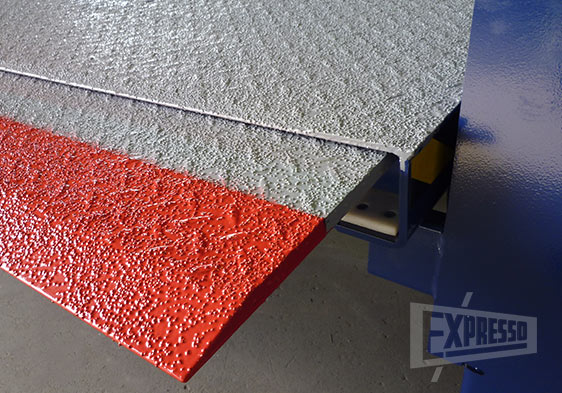

C) Non-slip coating for dock leveler

To improve grip and reduce rolling noise, nonslip soundproofing paint made from grained epoxy resin can be added as an option to loading decks and dock levellers. It is also possible to add a red safety marking materialising the minimum area of the leveler lip (150 mm) that must be in contact with the trailer to ensure safe transhipment.

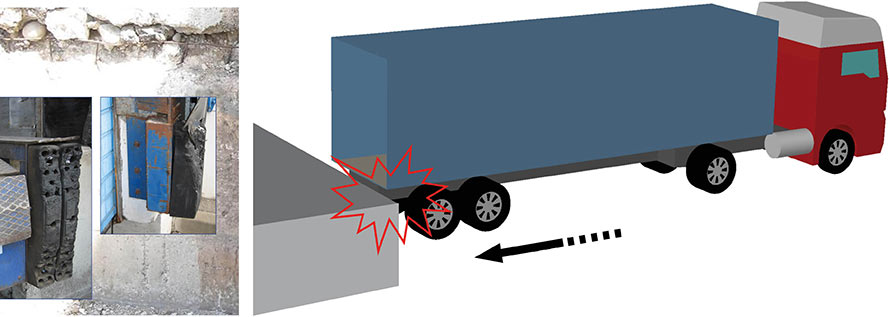

The repeated impacts of trucks on insufficiently protected loading docks lead to the inevitable deterioration of the buildings, structures and dock equipment.

A) Mobile dock bumpers - Durable dock protection

Protect your docks effectively and long-lastingly using the Expresso mobile bumpers Expresso

As trucks with pneumatic suspension are on the increase, static dock bumpers (classic) cannot withstand the pressure (vertical up and down movement) exerted during transshipment operations for very long. The rubber then rapidly deteriorates. Once the bumpers have been destroyed, it is the building that suffers the vehicle impacts. The solution: mobile bumpers.

The solution :

The mobile dock bumpers, they permanently follow the variations in vehicle height.

English

English Français

Français