External frame for dock leveler - Leveler pits - Tunnels

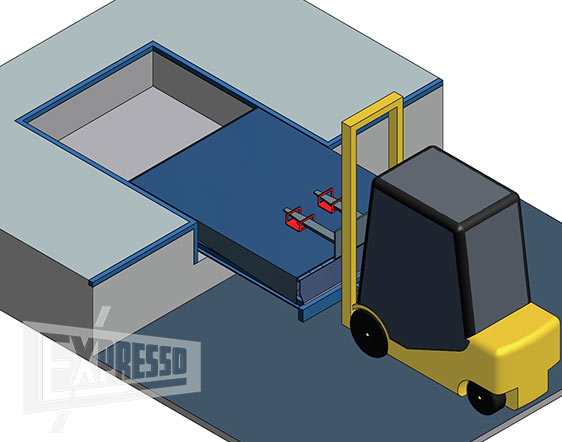

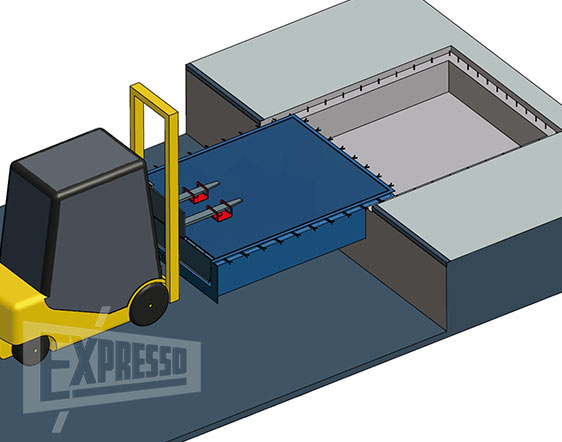

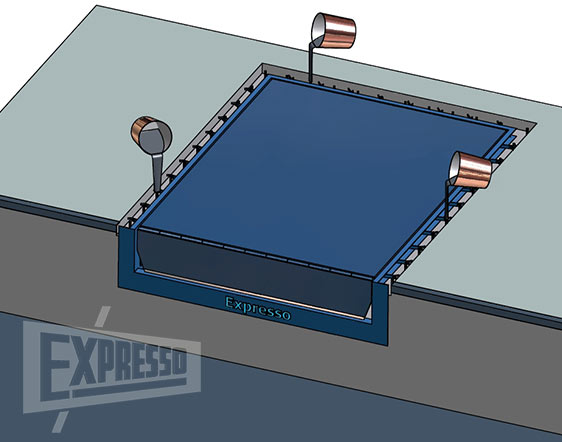

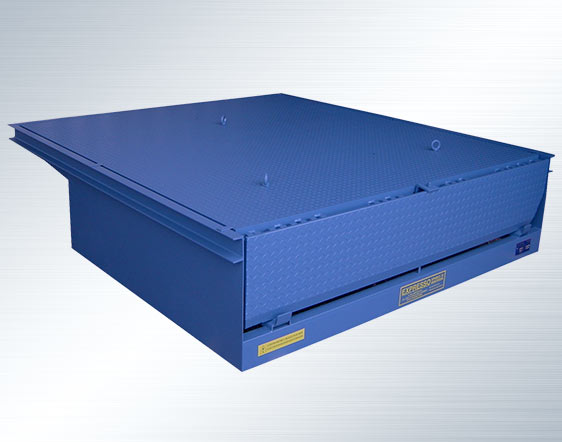

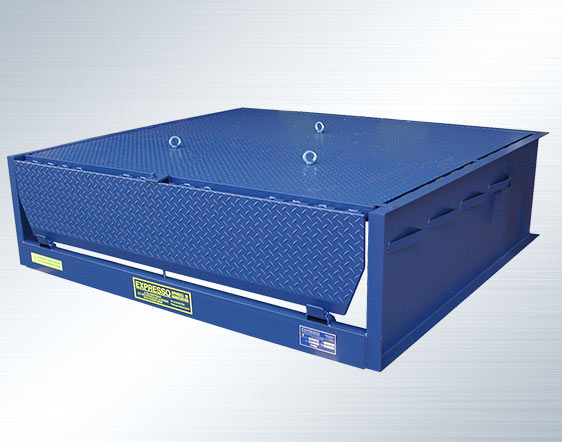

External frame for dock leveler

External frame - Sidewalk frame - Frame with removable sides

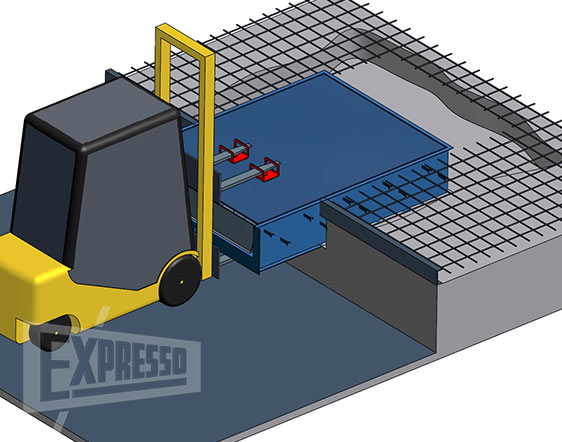

The external chassis for dock levelers is a solution without civil engineering: When the configuration allows it, and the yard depth is sufficient, the leveler on a self-supporting frame is a very good solution.

- External frame with guardrails or safety rails

- External frame with space for tail lift

- Internal frame to fit into existing pits

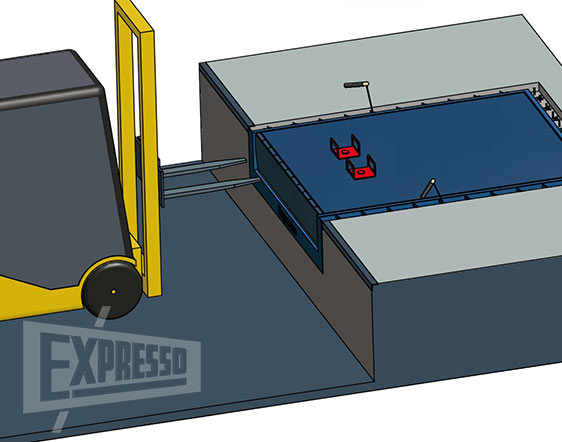

- Extended external frame with loading tunnel comprising a metal frame for the cladding (or tarpaulin) and a dock shelter

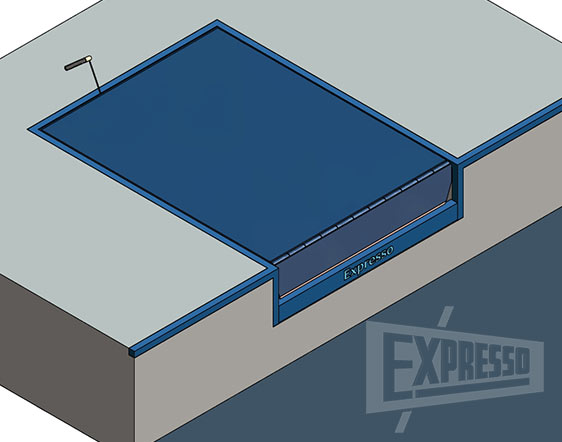

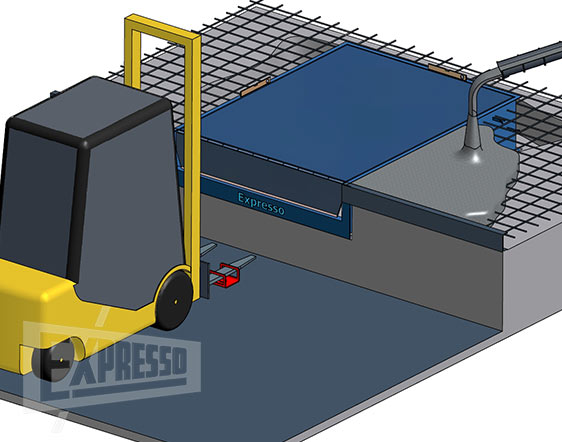

Loading tunnel for dock leveler

with metal reinforcement, cladding (or tarpaulin) and dock shelter

Space-saving inside buildings - Protection against the cold and bad weather thanks to the loading tunnel

Dock tunnels for levelers on external frame allows to ensure comfortable working conditions, as well for staff as goods transhipped, especially when the building does not have dock roof in the loading area, or this one is too short.

The loading tunnel includes:

Types of pits for levelers

1) Leveler for pit with outside steel angles

(with or without tailback reserve)

The leveler is equiped with a back steel angle which will be welded on pit angle.The front cross bar will be welded sur the vertical pit angles.

- No additional civil engineering

- Easy subsequent leveler removal

- High engineering cost

- obligation of welding operation during installation

2) Leveler for pit with rabbet for self-carried upper frame or hanged frame

(with or without tailback reserve)

The leveler shows on its upper part, a peripheral frame with wall anchors on 3 sides, which will be putted on the rabbet around the pit.Wall anchors will be welded on the resting concrete steel, than concrete is underpoured up to ground level.

- Low engineering cost

- Fast assembly without apparent welding

- civil engineering after installation

- Later uninstall difficulties

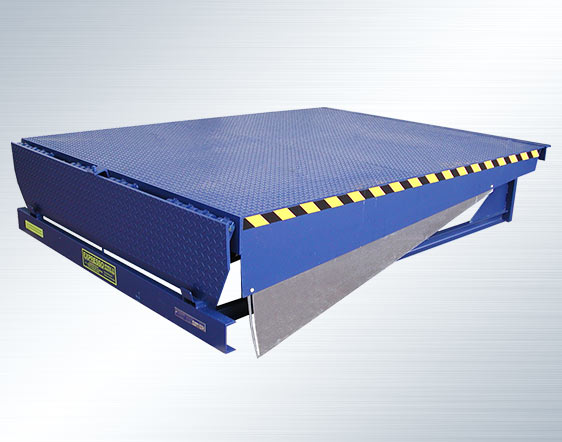

3) Coffered leveler (formwork) for non defined pit

(with or without tailback reserve)

The leveler is fully coffered on 3 sides which are equiped with wall anchors. It is putted on the bed plate equiped with resting concrete steel on the 3 sides which will be welded on wall anchors and then filled with concrete.

- Low engineering cost

- No additional civil engineering

- Fast assembly without apparent welding

- Difficulty of de-installation

4) Adaptations in an existing pit

As part of a dock renovation, we adapt the leveler at the existing pit. The leveler is custom made.

English

English Français

Français